Here’s the starting point. An empty van just waiting for a floor!

Objectives:

— plywood to cut down on noise

— solid fit

— create a storage area below finished van for materials transport.

I selected 3/4″ poplar plywood for the floor. It’s about $40 a sheet, very solid, and has a clear, smooth, sanded finish. The 12′ cargo area required 3 sheets, cut to 4′ x 6′ panels. Cardboard templates made the job easier.

The 3 base pieces were cut, adjusted and lined with a thin pad to cushion the contact with the metal floor.

Base floor completed and bolts to the metal floor at the hold down points.

I decided to add a basement. It will be an area under the finished floor, that provides space for storage of items. In addition, 4′ x 8′ sheets of plywood can be transported from the lumber yard back home without intruding on the finished space above the main floor. First a set of 4 1/2″ joists were bolted into the base floor, in a configuration to allow lots of space.

The space where the blue blanket is will hold a few full sheets of plywood. The front storage is designed to hold two folding chairs for use outside the van.

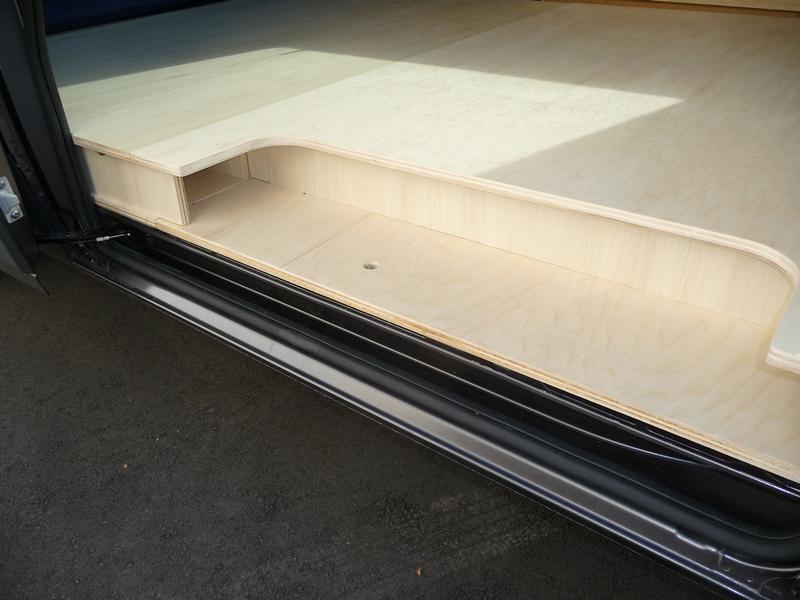

Here you can see the “basement” area from the loading area in the back of the van. The space is 52″ wide. When not transporting plywood, two 4 1/2″ temporary joists are slid in to better support the top floor for regular use.

At the sliding door entry, a step is provided to offer the (industry leading) low step-in height of the Promaster, with a step up to the actual floor.

A vinyl floor is to be added soon!